Are you ready to share your problems with us?

With sales support or technical department, you can help us improve our products

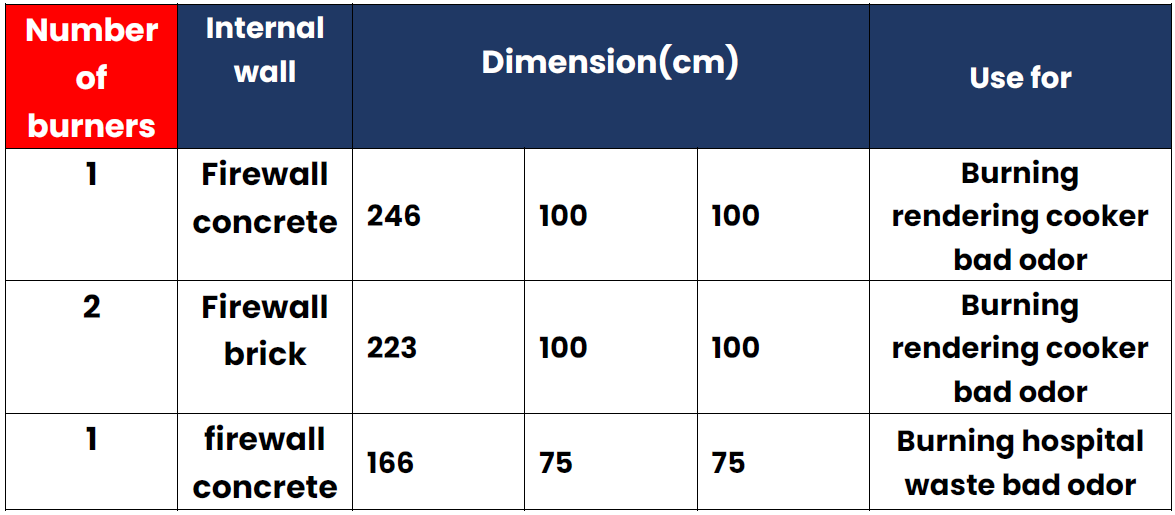

The presence of unpleasant odors can be classified as pollutants that have a negative effect on quality of life. Since some production processes such as cooking protein waste (incubation and slaughterhouse), decontamination of infectious waste or the process of producing meat and fish powder create a very unpleasant odor, odor control is one of the important environmental priorities of these factories. Although there are various methods to control odor, but most of them are costly and complex methods that are difficult to implement and control in small production units common in the country.

Currently, the most desirable and effective odor control system is burning method. In this method, the exhaust air is heated to 700-800 ° C for 1-2 minutes. In this case, the odor-producing compounds are oxidized and the unpleasant odor is eliminated. Due to the special design of the surface inside the device and refractory work inside it, it is easy to achieve temperature and durability conditions in the above time.

With sales support or technical department, you can help us improve our products