Are you ready to share your problems with us?

With sales support or technical department, you can help us improve our products

With the expansion of the dairy products industry in the country and the urgent need to supply milk, we are witnessing an increase in the number of livestock farms across the country, and as a result, the production of animal waste will be one of its problems. In addition, considering the establishment of laying hens in all parts of the country, one of the problems of this industry is the mass production of chicken droppings. These wastes are considered among environmental pollutants that, if discharged into the environment, increase the BOD and COD of water, and also put pressure on the health of the community by spreading diseases from one region to another. The livestock and poultry waste processing system of Khaz Electric Company has been able to solve this problem with the aerobic approach and the following advantages.

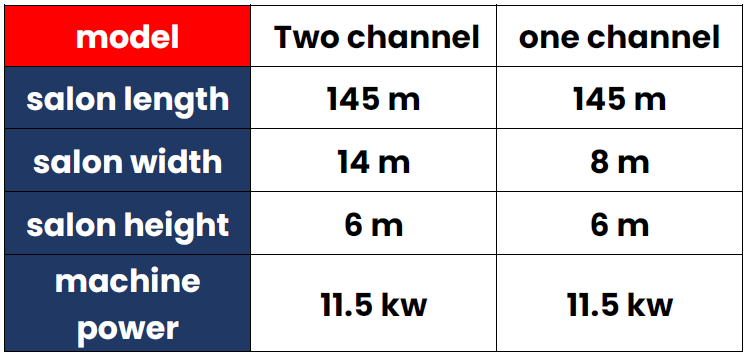

The livestock and poultry excrement processing system of Khazar Electric Company is a bioturner that moves in the hall with a light structure on rails and performs aeration by the site of channels and the movement of paddles. With the action of aeration and intensifying the fermentation, the temperature of waste reaches more than 65 to 70 degrees Celsius, in which case all human and animal pathogens as well as the weed seed will be destroyed. The capacity of the machine is 50 tons per day in double channel mode and 25 tons per day in single channel mode. The process is continuous and when the waste enters the beginning of the line, after about 28 to 32 days, the organic fertilizer is dry and packable. In the livestock and poultry waste processing system, the input humidity should be between 65 and 70% for the process to go aerobically.

With sales support or technical department, you can help us improve our products